Description

Laser Welder GWL

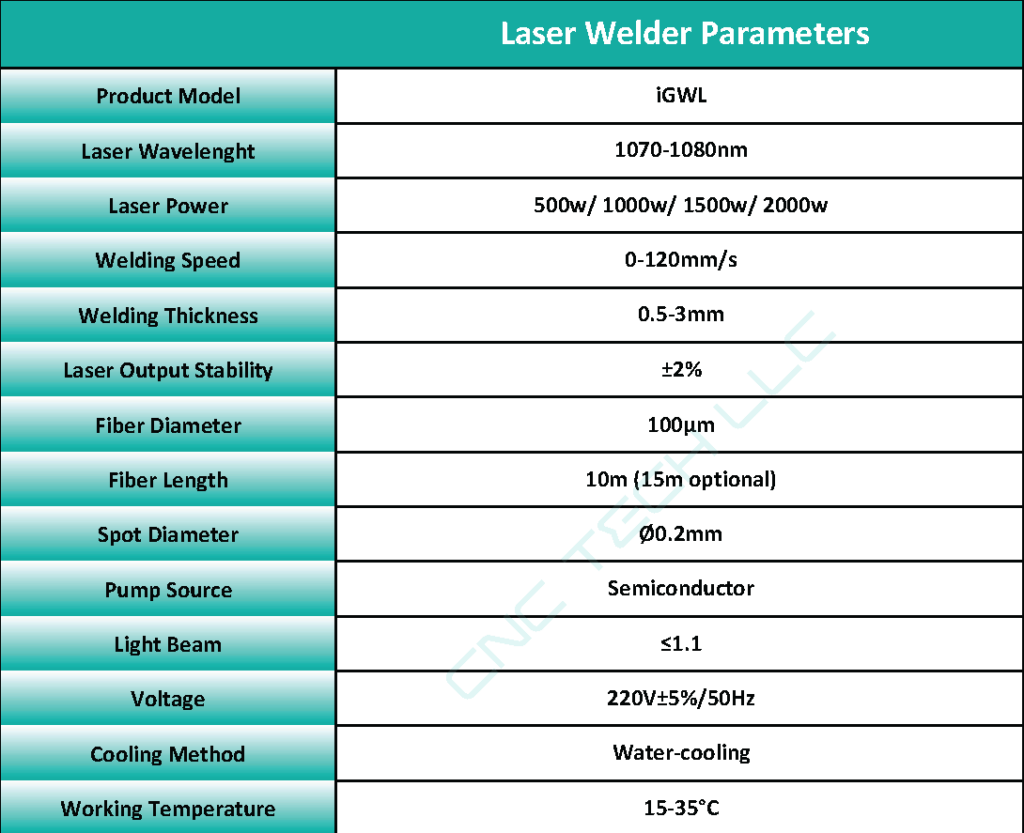

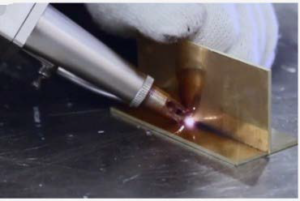

This innovative machine utilizes focused laser beams to melt and fuse metal parts. Laser beams provide precise control, flexibility, and numerous advantages over traditional welding processes. Employed by manufacturing experts across all industries, they offer a wide range of applications. They are particularly valuable for precision welding, joining small metal parts, and performing intricate welds. These machines provide low maintenance, non-contact welding, high-quality precision, efficiency improvements, and consistent part quality, all while keeping costs down and productivity high.

Laser welding can be used for welding various metals and alloys, including titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, silver, and others. It is also applicable for welding dissimilar metals such as copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, and low-carbon steel-copper.

12900

Additional information

| Power Consumption | 5-11 kW Circuit Braker Requirements 30-55 Amp |

|---|---|

| Dimensions | 24" (L) x 38" (W) x 33" (H) |

| Safety | It is worth noting that this laser is classified as Class #4, and clients should be familiar with the essential safety requirements associated with its operation. |