ADVANCED CNC AND LASER SOLUTION

WELCOME TO CNC TECH

Your Ultimate Destination For Laser Cutting And Cleaning Equipment

ADVANCED CNC AND LASER SOLUTION

WELCOME TO CNC TECH

Your Ultimate Destination For Laser Cutting And Cleaning Equipment

ADVANCED CNC AND LASER SOLUTION

WELCOME TO CNC TECH

Your Ultimate Destination For Laser Cutting And Cleaning Equipment

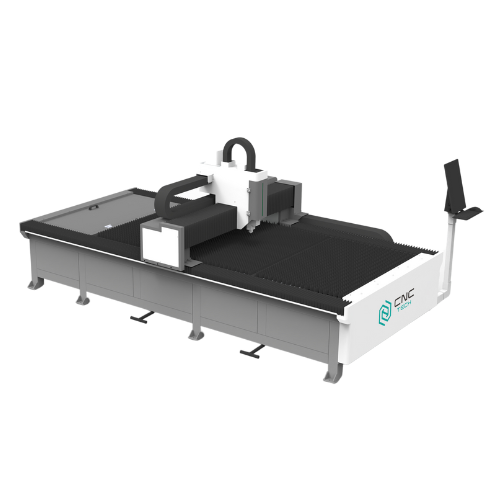

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

Sheet Metal Cutting Machine

THE CUTTING EDGE

TECHNOLOGY

CNC TECH is a reliable company that specializes in manufacturing and distributing CNC and laser equipment. As a supplier, we are committed to delivering exceptional products and services with endless possibilities, which are unmatched in the industry. With our extensive experience, we provide installation and support services to diverse businesses. Our dedicated customers benefit from cost-effective prototype testing and mass production with the aid of our high-quality products.

At CNC TECH, we prioritize honesty and integrity in all our endeavors and strive to surpass customer expectations through our value-added solutions. We believe in the power of collaboration and cooperation to achieve more.

SERVICES

Experience the convenience and reliability of CNC TECH, your one-stop shop for all laser needs. Our comprehensive solutions include sales, service, and repair of top-of-the-line laser equipment, ensuring all your requirements are met under one roof.

Take advantage of our specialized consultation services, customized CNC system blueprints, and comprehensive training and support solutions. We are deeply committed to ensuring your success, offering a 2-year warranty, swift spare parts delivery, and continuous technical support to empower your business

Choose CNC TECH Service for the ultimate in laser solutions and let our expertise fuel your success.

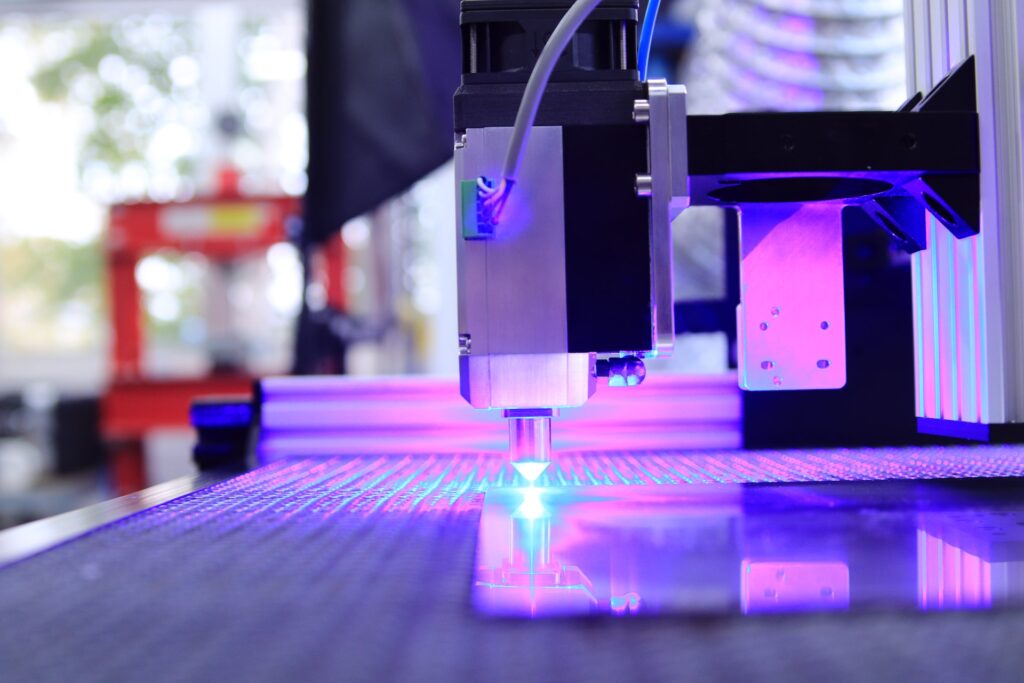

AUTO-FOCUS LASER CUTTING HEAD

The auto-focus laser cutting head is equipped with a motor drive unit and a linear mechanism that enables the focusing lens to automatically adjust its position within a 20mm range. Through the program, users can set continuous focus, allowing for rapid perforation of thick plates and automatic cutting of plates with varying thicknesses and materials. The cutting head is also equipped with a compound lens group that integrates the light beam, optimized for both optical and water-cooled design, ensuring stable and long-term operation.

The cutting head has been optimized with a smooth and efficient airflow design, improving the cutting effect. Its auto-focus range can adjust between +10mm and -10mm, with an adjustment accuracy of 0.01mm and a speed of 100mm/s. The protection lens features a dust protection design, safeguarding the internal optical components. Additionally, by increasing the distance between the protection lens and the nozzle, the lens’ lifespan is extended. The cutting head also features a drawer-type lens holder, allowing for fast and simple replacement of the protection lens.

The QBH connector of the cutting head is not limited, making it compatible with various lasers that feature the QBH connector. Thanks to its auto-focus capabilities, this cutting head saves 10 times the focusing time, thus boosting work efficiency. Lastly, the cutting head’s service life is extended through optimized structural design.

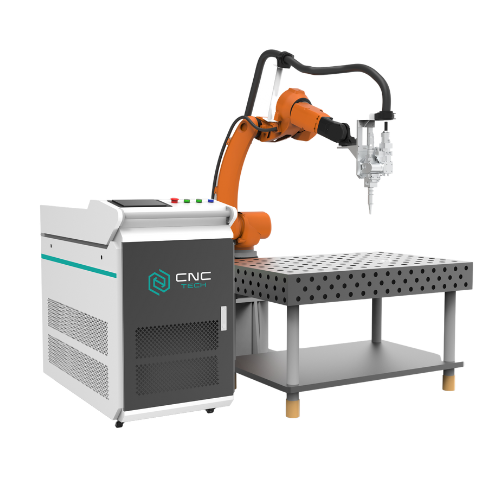

HEAVY-DUTY WELDING BED

The heavy-duty welding bed is constructed using a thick rectangular tube with a diameter of 200*200mm. The square tube welding bed can support up to 1 ton of weight. The bed undergoes annealing and milling by a large gantry to precisely drill all the necessary installation holes in one go. This results in higher tensile strength and dimensional stability, leading to improved accuracy in workpiece processing and increased resistance and stability of the guide rail.

Using this welding bed reduces the loss of the metal laser cutting machine and ensures long-term precision and stability for up to 20 years without deformation. Furthermore, the equipment offers excellent stability, reducing processing errors caused by bed vibrations.

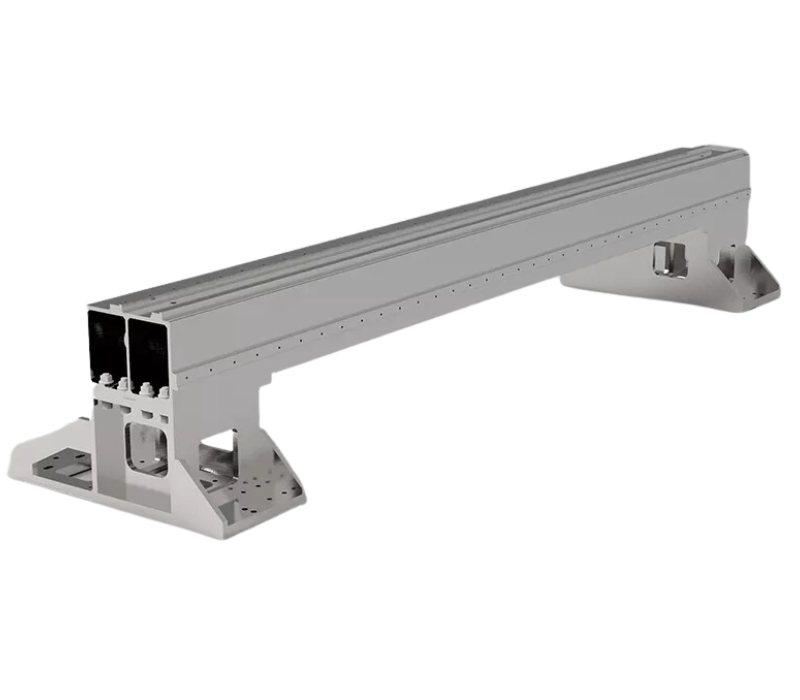

AEROSPACE ALUMINUM EXTRUSION BEAM

The aerospace aluminum extrusion beam offers several advantages for processing purposes. Firstly, it boasts high precision due to undergoing manual aging, solution treatment, and finishing, resulting in excellent integrity, rigidity, toughness, and ductility. Secondly, its light weight and strong rigidity make it ideal for high-speed processing, while its high flexibility allows for fast cutting of various shapes with great precision. Lastly, its lighter weight ensures rapid equipment operation and improves processing efficiency, without sacrificing quality.

Utilizing this high-quality aluminum beam not only guarantees the best laser cutting machine’s high-speed performance, but also enhances the cutting processing’s accuracy and efficiency. It effectively extends the metal laser cutting machine’s lifespan while reducing both time and cost. Furthermore, even after prolonged use, the aluminum beam can maintain cutting precision, while also mitigating the laser head’s kinetic energy during high-speed movements.

HAPPY CUSTOMERS

TESTIMONIALS

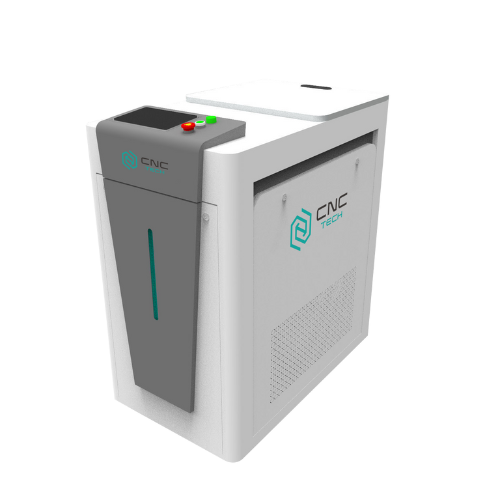

LASER CLEANING MACHINES

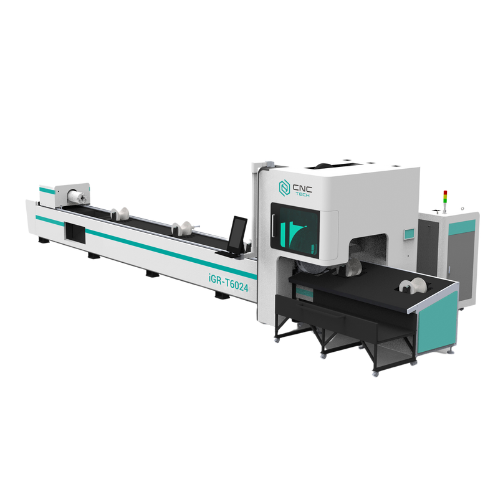

EXPLORE OUR

CATEGORIES

Discover our diverse product categories, designed to cater to your every CNC and laser need. Our Laser Cleaners provide efficient and precise cleaning solutions, while our Fiber Laser Cutters and Fiber Laser Tubing Cutters offer unparalleled accuracy and speed for cutting tasks. Complement your equipment with our range of high-quality Accessories to maximize productivity and create a seamless workflow.