The subsequent inventory outlines key factors that should be taken into account by laser users or those considering the use of laser systems.

Prior to using the product, it is essential to read and comprehend the User’s Guide, as well as familiarize oneself with the operating and maintenance instructions provided. If there are any ambiguities or uncertainties, contacting the manufacturer should not be delayed.

All individuals present in the vicinity must wear appropriate laser safety eyewear before laser emission is initiated, including those who are not directly involved in operating the laser system.

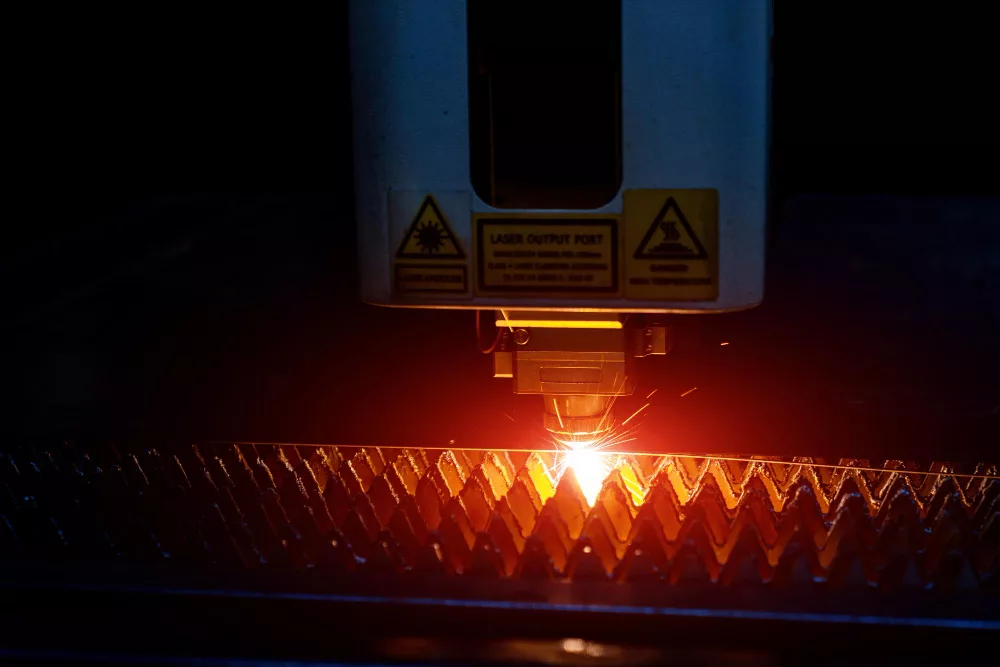

When the power is on, one should never look directly into the laser output port. The laser and all optical components employed with it should be set up away from eye level.

Fibers or collimators should not be installed or terminated while the laser is active. When working with the output, such as mounting the fiber or collimator into a fixture, the laser should always be switched off. If necessary, the output should be aligned at low output power before gradually increasing the output power.

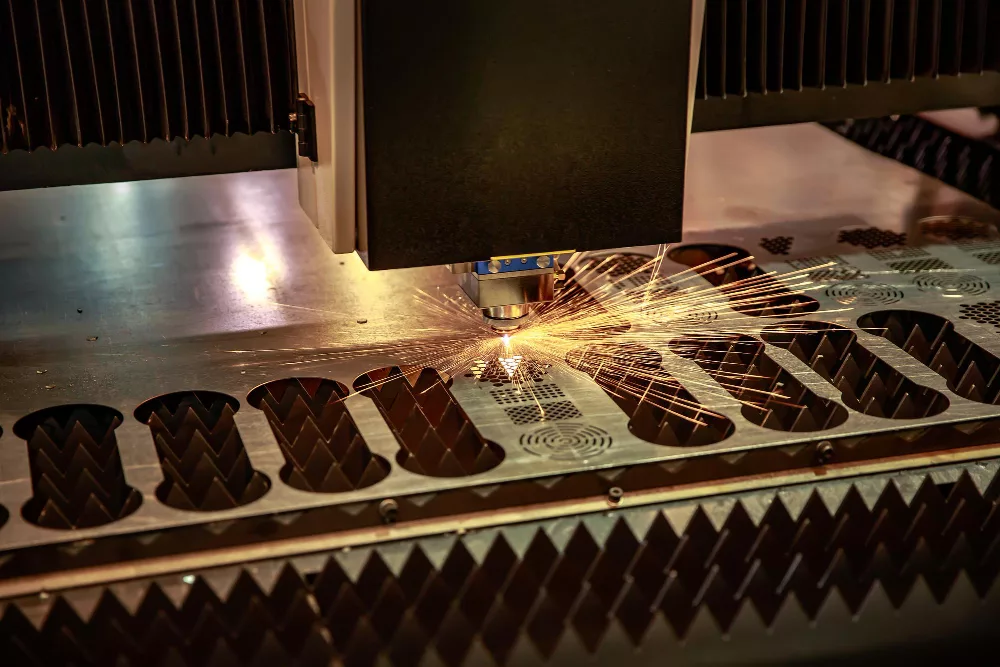

The interaction between the laser and the material being processed can generate high-intensity UV and visible radiation. As a result, laser enclosures should be in place to prevent eye damage from visible radiation.

To avoid additional safety hazards posed by gases, sparks, and debris generated from laser interaction with the work surface, ensure that the work surface is properly vented.

The laser should be used in a room with access controlled by door interlocks, warning signs should be posted, and access to the area should be limited to individuals who are trained in laser safety while operating the laser.

It is best to avoid using the laser in a darkened environment. Enabling the laser without a coupling fiber or equivalent attached to the optical output connector should also be avoided.

The operator of the laser bears the responsibility of notifying others about laser usage and controlling the laser area.